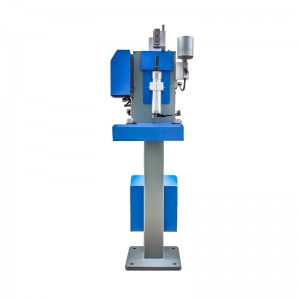

KELEI Robot-use Laser Welding Torch

Features

1. Precise collimation and superior liquid-cooled design ensures the reliability and stability of the torch

2. Optimized optical design and smooth airflow helps improving consistency

3. Multiple choices of connectors that brings a broader compatibility

4. Solid QBH connector on the torch secures the operation safety

5. Modular manufactured body with rigid protection lens prevents dusts and obstacles from the focus lens, thus prolongs the service life

Specification

|

Laser Power |

≤2000W |

≤4000W |

|

Collimation |

100mm, 120mm, 150mm |

60mm, 75mm, 100mm, 125mm, 150mm |

|

Focal Length |

150mm, 200mm, 250mm, 300mm |

150mm, 200mm, 250mm, 300mm, 350mm, 400mm |

|

Nozzle Size |

8mm |

|

|

Focal Range |

±5mm |

|

|

Air Pressure |

<0.6Mpa |

|

|

Fiber Connector |

GBH, QCS |

|

Connector Type: QBH

Collimation Lens: PMD30T5

Wavelength: 1080±10nm

Focus Lens: PMD30T5

Power: 2KW, 4KW

Gas Output: Coaxial or paraxial

Collimation Focal Length: 100mm, 150mm

Focal Length: F200, F250, F300

Gas Pressure: ≤1Mpa

Weight: 3.2KG

Support

Manual, Accessories

Products and Applications

Popular science product knowledge

Why should we select robotic welding?

1. Increasing working efficiency

2. Lowering the labor’s workload and be capable for work under hazardous environments

3. Lowering training requirements for workers

4. Increasing the consistency and quality of welding, which can be reflected by objective data